MRB (Material Review Board) Warehouse Overview

The MRB (Material Review Board) Warehouse is where rejected material found at time of PO receiving or in production is transferred through inventory handling into the WHSE so management has time to determine whether to return discrepant material to the Supplier. It is a non-netable account meaning qty's residing in this WHSE are not consider as available inventory for MRP demands or production needs.

|

Enter the SQLMANEX.EXE (within the ManEx root directory)

This action will then prompt the user for a password

|

|

|

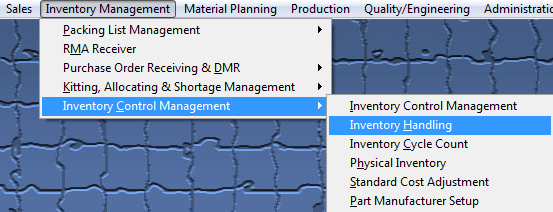

The following screen will be displayed, select Inventory Management/Inventory Control Management/Inventory Handling

|

|

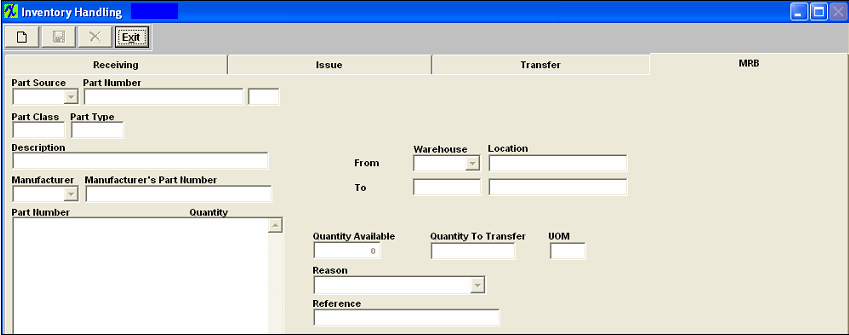

The following screen will be displayed:

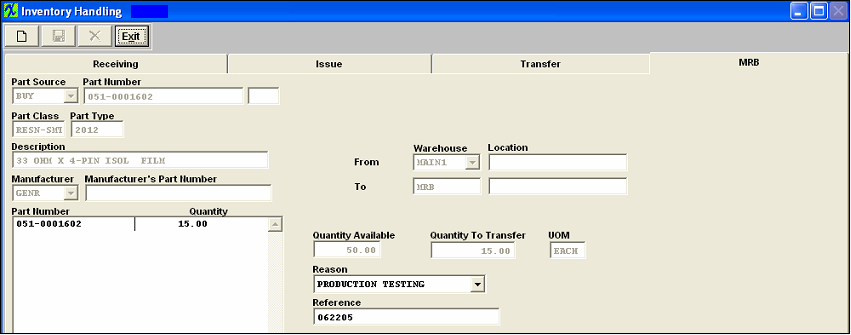

Depress the MRB tab. The following screen will be displayed.

To Transfer Inventory Items from Inventory to MRB follow these steps.

- Depress the Add button.

- Enter in your password.

- Select the Part Source from the pull down menu. (BUY, MAKE, or CONSG)

- Enter the Part Number, if Part Source is "CONSG" you will need to enter Customer Name from pull down, then you will have a choice to enter in customer PN or Internal PN.

- Part type, class, and description will default in.

- Select the manufacturer & manufacturer part number from the pull down list.

- Select the From Warehouse from the pull down list:

- The To Warehouse automatically defaults to MRB (Material Review Board).

- Enter the Quantity to Transfer.

- Select the Reason for transfer from the pull down list:

- Enter in the Reference if applicable.

- Depress the Save button.

|

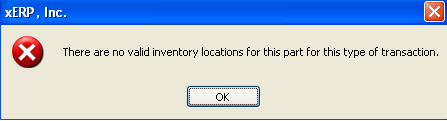

This message is a general message that is displayed in Inventory Handling if all locations/AVL's for a part are flagged in a Cycle Count or Physical Inventory and the part has ONLY one WHSE and AVL setup.

User must reconcile and post the cycle count or physical inventory for this part and then you will be able to process the records within Inventory Handling.

|

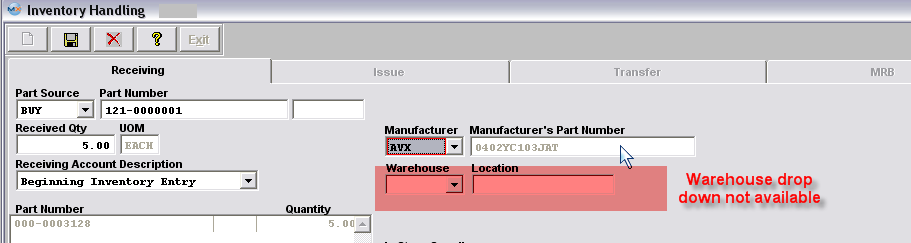

If the part has more than one WHSE and/or AVL setup and the part number is flagged in a Cycle Count or Physical Inventory the warning is NOT displayed, but the warehouse drop down is not avaiable for selection within the issuing, receiving, transferring, and MRB screens after you select the AVL. As shown in the screen below.

The completed screen will appear as follows:

Once the preceding steps have been completed, the user may Add to PO DMR (Discrepant Material Return) module, or you may transfer it back into Inventory using the Transfer tab .Once the DMR (discrepant material return) has been added and saved, a Debit Memo will be created in the Accounting System. Additionally, the corresponding entry will be created and the balance in the Accounts Payable Aging will adjust.

|