|

Enter the SQLMANEX.EXE (within the ManEx root directory)

This action will then prompt the user for a password

|

|

|

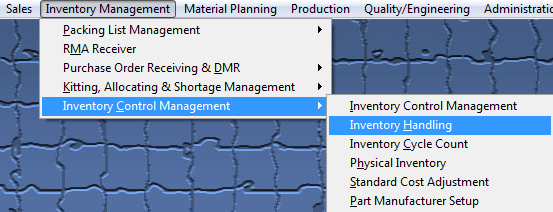

The following screen will be displayed, select Inventory Management/Inventory Control Management/Inventory Handling

|

|

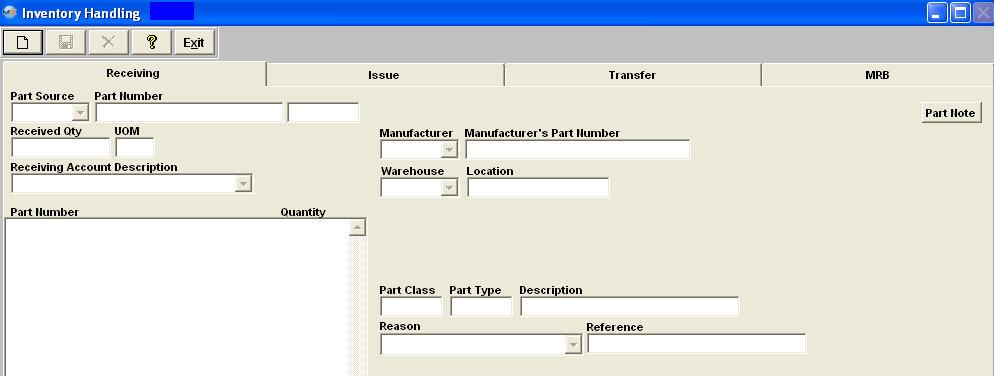

The main screen will be displayed:

Inventory Handling is used for receipt of non-purchase order receipts.

To add inventory, depress the Receiving tab.

- Depress the Add button.

- Enter your password.

- Select the Part Source from the pull down menu (BUY, MAKE, or CONSG).

- Enter a Part Number, if Part Source is "CONSG" you will need to enter Customer Name from pull down, then you will have a choice to enter in customer PN or Internal PN.

- Part type, class, and description will default in.

- Enter the Received quantity.

- Select the Receiving Account Description from the pull down menu.

- Select the Manufacturer & manufacturer part number from the pull down list.

- The warehouse will default in. If the default is not the warehouse you want you may select a dffferent warehouse from the pull down list.

- Select the reason for the receipt from the pull down list.

- Enter in a Reference (Optional).

- Depress the Save button.

|

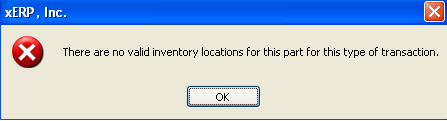

This message is a general message that is displayed in Inventory Handling if all locations/AVL's for a part are flagged in a Cycle Count or Physical Inventory and the part has ONLY one WHSE and AVL setup.

User must reconcile and post the cycle count or physical inventory for this part and then you will be able to process the records within Inventory Handling.

|

If the part has more than one WHSE and/or AVL setup and the part number is flagged in a Cycle Count or Physical Inventory the warning is NOT displayed, but the warehouse drop down is not available for selection within the issuing, receiving, transferring, and MRB screens after you select the AVL. As shown in the screen below.

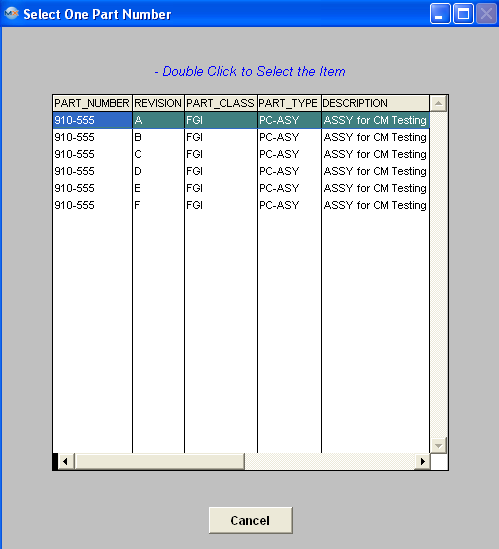

If there are multiple revisions for the same part number a screen will appear for user to select the correct part number from:

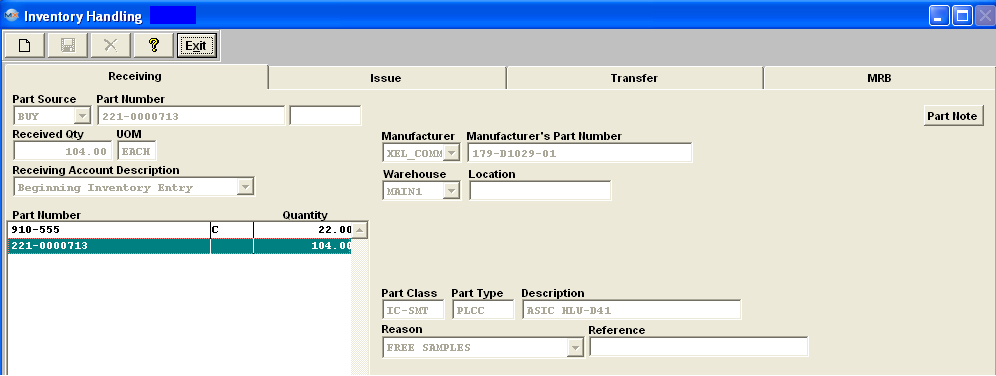

The completed screen will look like this for a Buy, or Make part.

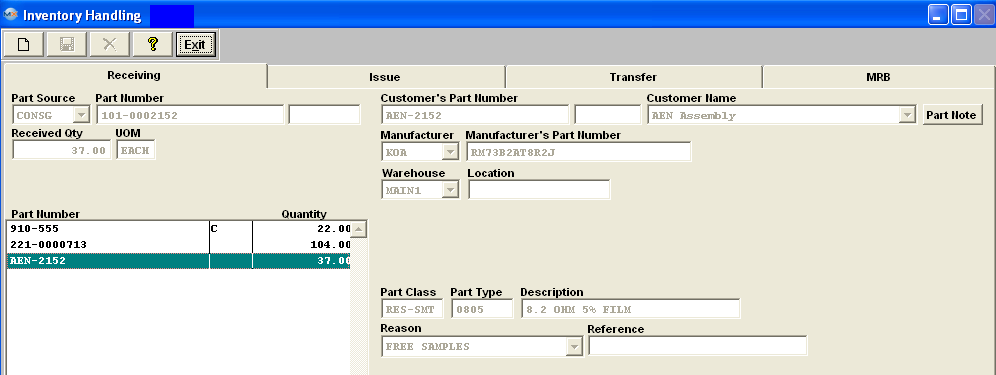

The completed screen will look like this for a Consigned part.

The completed screen will look like this for a Serialized part. Note: Users are allowed to receive in once issued out SN(s) back into stock, if the SN is for the same part number, and was issued out through inventory handling, then the system will re-link it to its old history. If the SN has been shipped out of the system via a packing list, then the user will be required to receive it back in through the RMA Process.

If user enters a SN that already exists for this PN they will recevie the following message:

Depress OK, then delete or remove the SN(s) being displayed in Red by depressing the Delete button and the following confirmation message will be displayed

Depress Yes to continue, then user must re-enter new serial numbers and save changes.

The completed screen will look like this for a Lot Coded part.

If the "Allow Auto Creating Location at Receiving" box has been selected for a specific AVL in the ICM module the "New Location" button will appear on the Receiving screen as shown below.

Depress the New Location button and the following screen will appear, giving the user the option to create a new Warehouse/Location for this part:

Depress "Yes" and the following screen will appear, listing the Warehouse(s) that have the "Allow to Auto Create Location at Receiving" box selected in the Warehouse Setup module.

If user selects InStore a Supplier selection will appear in the screen:

When all the information has been entered the New Warehouse/Location will appear in the Quantity Info screen within the ICM module.

|