Q. Is there a report that will give you the Detail of a Kit Closure Variance?

A. It would be difficult to recreate the variances for the following reasons:

For the Configuration variance, we would have to list the complete costed BOM for the assembly, as well as show the standard MATERIAL cost for the assembly. But both would be dependant on the values AT THE TIME of the transaction to FGI. And for that reason, looking at the current costs may not yield the same answer. So the costed BOM would have to be based on the same date as each transaction was processes. And the standard Material cost of the assembly has to be the same as it was at the time of transaction. And that is the essence of the report as it shows now. I don’t think we could determine the specifics of any one component involved in the generation of the configuration variance. And if they do cost rollups, they can make sure that there are no configuration variances (until they change the standard cost of the components or assembly or change the quantity of the components, or add or delete components).

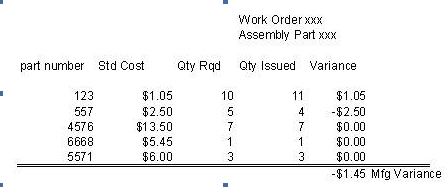

For the Manufacturing Variance, we take the sum of the components actual issued to the work order at their standard cost at the time of the kit close and bounce if off of the costed BOM at the time of the kit closing. (Configuration variance already addresses the difference between the standard cost and the bom cost.) So in this case, it may be possible to create a report that lists the components and their costs based on the BOM, and compare it to a list of the components and their costs actually kitted. It might look something like:

|