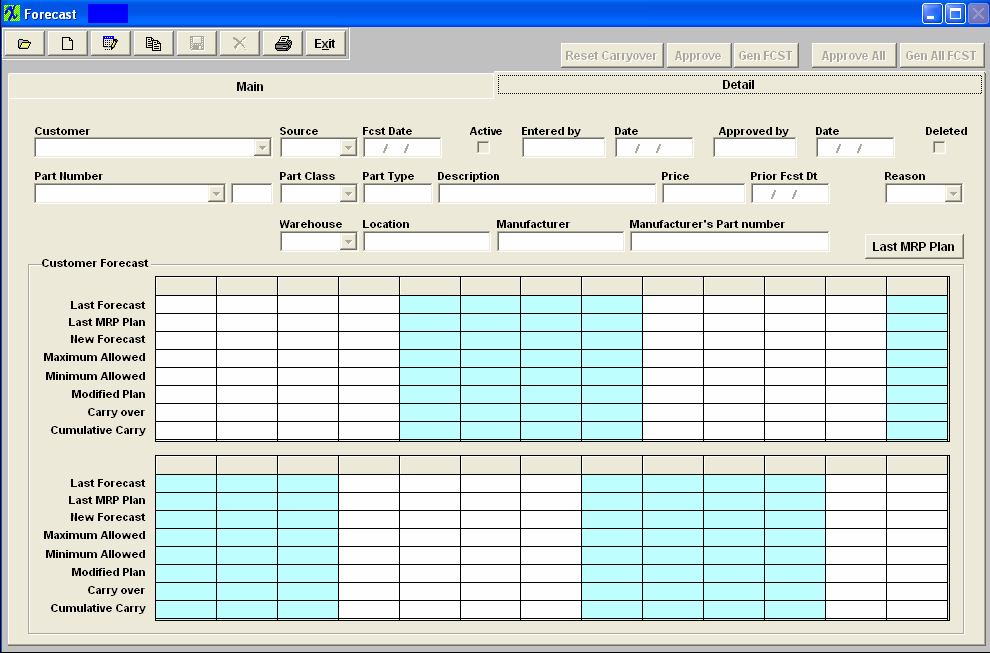

| Detail |

Fields and Definitions

| Customer |

The name of the customer providing the forecast

|

| Source |

Part Source - Make, Buy

|

| Fcst Date |

The date the forecast was originated

|

| Active |

Current forecast, as opposed to history or pending forecast

|

| Entered By |

User initials entering forecast

|

| Date |

Date of original forecast

|

| Approved By |

Initials of person approving the forecast

|

| Date |

Date of approval

|

| Deleted |

A forecast that has been made inactive - history

|

| Part Number |

The part number for the forecast listed |

| Part Class |

The classification of the Part. |

| Part Type |

The Type assigned to the part number. |

| Description |

The description of the Product or Part Number. |

| Price |

Price was intended to be utilized for forecasting revenue - not developed any further |

| Prior Fcst Date |

The most recent forecast created prior to the current active forecast.

|

| Reason |

The reason the prior forecast was made history.

|

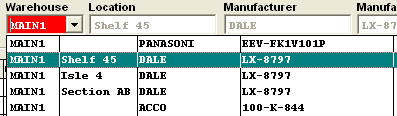

| Warehouse |

This field will only be displayed if it is a "BUY" part. Select the Warehouse from the Pull down.

|

| Location |

This field will only be displayed if it is a "BUY" part. This will default in upon selection of warehouse.

|

| Manufacturer |

This field will only be displayed if it is a "BUY" part. This will default in upon selection of warehouse.

|

| Manufactuer Part Number |

This field will only be displayed if it is a "BUY" part. This will default in upon selection of warehouse.

|

Action Buttons

|

The purpose of this function is to get the snap shot of the carry over data into the history table and capture the carryover clear date. This clear date is been used in the MRP logic to get the total consumable sales orders and total shipments against the forecast. By using this date we can get the total sales order due, and shipments from the reset date to current date.

The reason a password is being asked for when depressing the Reset Carryover button is because it is the same as making an edit to the screen, so it is proper to request a password to clear the carryover quantities.

You can print the carry over history by selecting the carry over reset date from the drop down in the report form on which you can see what was the carryover was over quantity at the time of reset.

|

|

Approve the forecast currently being displayed. The approval requirements means that the whole forecast is approved to be used in running MRP, not for any specific changes to the forecast. Without the approval, the forecast will not replace the prior forecast and be ready to use by MRP (unless no approval is required). If no approval is required in the system setup, then any user with edit rights can render the old forecast that has history and make the new one active for MRP.

|

|

Generate a forecast based on the “New Forecast”, the “Last Forecast” and the Forecast Allowed Tolerance for the customer involved |

|

Approve all Forecasts currently in pending status. The approval requirements means that the whole forecast is approved to be used in running MRP, not for any specific changes to the forecast. Without the approval, the forecast will not replace the prior forecast and be ready to use by MRP (unless no approval is required). If no approval is required in the system setup, then any user with edit rights can render the old forecast that has history and make the new one active for MRP. |

|

Same as Gen FCST, except does so for all forecasts in the system |

|

Shows what the last MRP requirements were. Will vary as transactions and MRP occur |

Customer Forecast

| Last Forecast |

The Last Forecast will be the values entered in the most recent previous forecast plan upon which MRP acted.

|

| Last MRP Plan |

The Last MRP Plan will be what MRP will be providing as a basis for component and work orders.

|

| New Forecast |

The New Forecast is the forecast being entered in the edit mode.

|

| Maximum Allowed |

The Maximum Allowed is the last forecast plan modified by the system setup tolerances. If the last FORECAST was for 100 units on the first week, and the tolerance was for 50%, then this line would have the number 150.

|

| Minimum Alowed |

The next is calculated similarly, showing the Minimum Allowed. So if the tolerance was 10%, then this line would be 90 units.

|

| Modified Plan |

The Modified Plan is the New Forecast modified by the constraints of the Maximum and Minimum allowed. In this example, no change is allowed, because of the system setup and the fact that we are in the current period. Notice in the 5th week, these numbers become active as it falls in the next period.

|

| Carry over |

The Carry Over is anything that is not covered by the forecast modified by the tolerances. Thus, if the previous forecast were 200, and the current forecast is for 300, and the tolerance is zero, the forecast could not be changed from 200 to 300, but held constant at 200. But the 100 left over that couldn’t be added to that week of the forecast becomes the carryover to the next week. As long as the tolerance allows it, the next week will be inclusive of the carryover. If it still falls outside the tolerance, it carries over to the following week. It will carryover until it can be absorbed into the forecast based on the tolerances for each period.

|

| Cumulative Carry |

The Cumulative carryover is simply adding up any individual carryovers to keep track of the total amount of “catch-up” that is required.

|

|

|

|

|

|

|

|

|

|

| Article ID: 2411 |