Some of our users were reporting that after they make changes to the BOM and return to the Kit to put the Updates in place that the quantity was not being brought forward into the update kit screen and was NOT returned to stock and seemed to have disappeared from the system.

Explanation:

If the user is simply just depressing the OK button that stock will be issued to the kit and not returned to stock. When you make changes to the BOM and then update the kit, make SURE that the users are trained to review and disposition every item listed and ensure that they are returning to stock if desired. They can NOT simply just depress the OK button, otherwise they can be issuing parts to the WO, and we can NOT get them back, they will be valued as a Manufacture Variance.

The system is operating as intended.

The reason why the parts are NOT re-appearing in stock is due to the Work Center and/or Part removal changes made on the BOM’s. If the Work Center was changed on the BOM the update kit does not have the original Part/Work Center combination to return the stock to inventory – this is why it defaults to Issue to WO with the option to return to Stock.

Same rule would apply if a part was deleted from a BOM and the kit updated. The kitting module would default issue to WO, because it did not have the original Part number information to return directly to stock. This is why it defaults Issue to WO with the option to return to Stock.

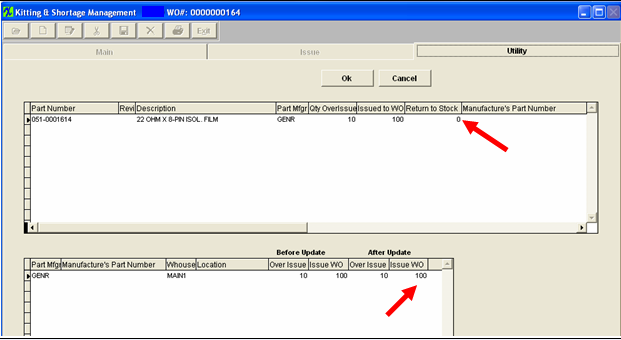

When you depress the update kit button the item is displayed on screen for disposition. If you take a look at the print screen provided you will see that it is defaulting the qty to be issues to the kit. If the user is simply just depressing the OK button that stock will be issued to the kit and not returned to stock. The value of that stock will be accounted for in the Manufacture Variance upon closing the kit. If you want the inventory to be returned to stock you need to change the qty in the Issue to WO section below to 0.00 and then the Return to Stock qty should update to the amount you wish to have returned to stock.

When you make changes to the BOM and then update the kit, make SURE that the users are trained to review and disposition every item listed and ensure that they are returning to stock if desired. They can NOT simply just depress the OK button, otherwise they can be issuing parts to the WO, and we can not get those back, they will be valued as a Manufacture Variance.

|