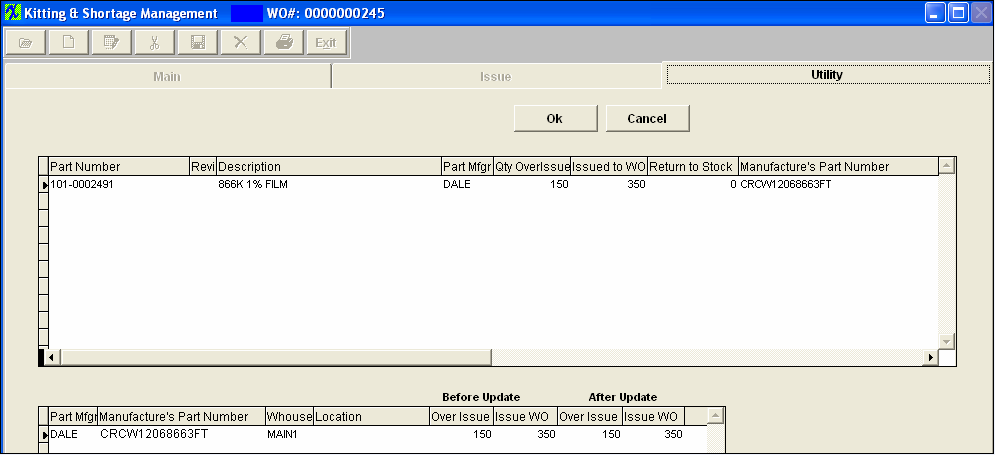

If the changes to the BOM reflect inventory parts that require dispositioning the following screen will appear:

Note: If parts are being displayed for dispositioning even though NO changes to quantities were made it may be due to the fact that the work centers were changed and upon completion of the update kit the parts will be issued to the WO (costed to the kit) and accounted for as a Mfgr Variance upon closing.

Highlight the item. The system will default in the issued qty into the Issue WO field (bottom screen). If you wish to issue the parts directly to the cost of the Work Order then you can leave the qty in Issue WO. Depressing the OK button will then issue and cost those parts to the kit. If you wish to return those part back to inventory you will change the Issue WO qty to 0 (bottom screen) and then you will see the Return to Stock qty adjust (top screen). That amount in the Return to Stock will be the amount that will be returned back to stock as available inventory.

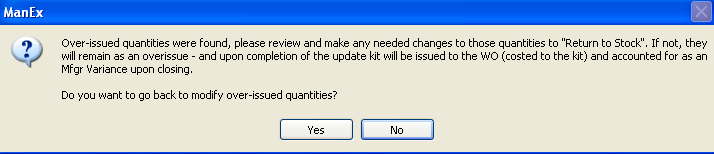

If there is an Over Issue Quantity found during the update kit, user will receive the following message to remind the user that there was an Over-issue qty found, and to make any needed changes to those quantities to "Return to Stock". (If you wish to return those part back to inventory you will change the Over Issue qty to 0 (bottom screen) and then you will see the Return to Stock qty adjust (top screen)). That amount in the Return to Stock will be the amount that will be returned back to stock as available inventory.

If not the over-issued qty will remain as an overissue - and upon completion of the update kit the parts will be issued to the WO (costed to the kit) and accounted for as a Mfgr Variance upon closing.

If the over-issued quantity or quantity in WO-WIP has been allocated to other work orders/projects, then the user will receive the following message and the kit will not update until the allocatiions have been cleared.

For any new parts added to the BOM, they will appear as shortages, and user will need to make sure to pull them to the kit.

If any of the quantities per within the BOM were increased, you will have to also pull additional amounts, which will now show as shortages to the Work Order.

If user changes a Work Center on a BOM and depress the Update kit button, the system will treat this part as a new item, and will appear as shortages and user will need to make sure and pull them to the kit.

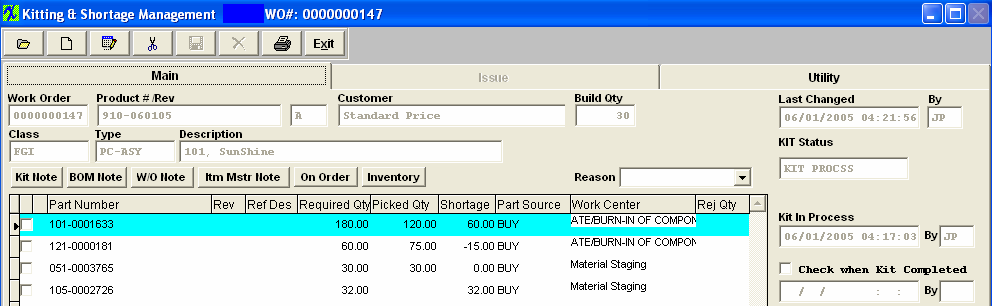

In the example below, part number 105-0002726 was just added to the BOM and must now be pulled. Additionally, part number 101-0001633 had the quantity per on the BOM increased and now the shortage must be pulled.