MRB (Material Review Board) Warehouse Overview

The MRB (Material Review Board) Warehouse is where the board members determine whether to return discrepant material to the Supplier.

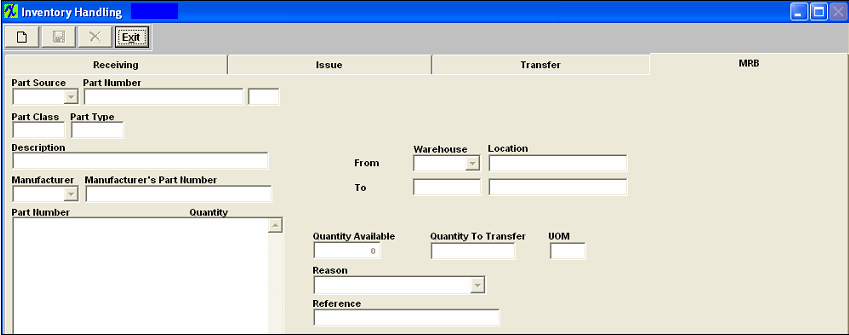

Depress the MRB tab. The following screen will appear.

To Transfer Inventory Items from Inventory to MRB follow these steps.

- Depress the Add button.

- Type in your password.

- Select the Part Source from the pull down menu. (BUY, MAKE, CONSG, or PHANTOM).

- Type in the Part Number, if Part Source is "CONSG" you will need to enter Customer Name from pull down, then you will have a choice to enter in customer PN or Internal PN.

- Part type, class, and description will default in.

- Select the manufacturer & manufacturer part number from the pull down list.

- Select the From Warehouse from the pull down list:

- The To Warehouse automatically defaults to MRB (Material Review Board).

- Type in the Quantity to Transfer.

- Select the Reason for transfer from the pull down list:

- Type in the Reference.

- Depress the Save button.

|

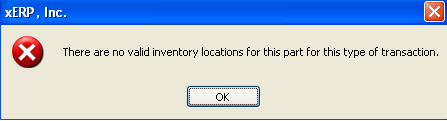

This message is a general message user gets when the program can not find any warehouse/location for this part number. This message will appear if the part is locked in cycle count or physical inventory. User must reconcile and post the physical inventory for this part and then you will be able to process the records within Inventory Handling.

|

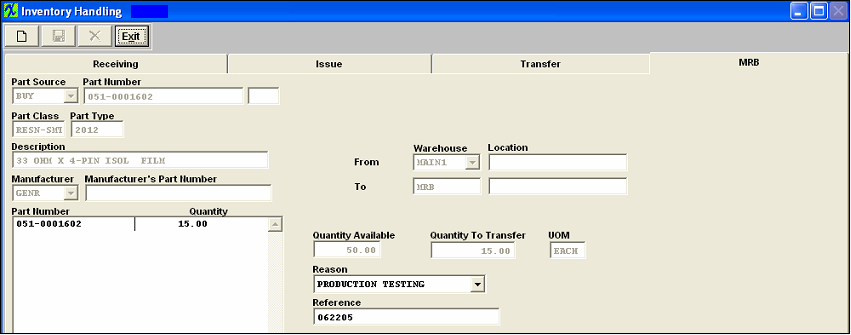

The completed screen will appear as follows:

Once the preceding steps have been completed, the user may Add to PO DMR (Discrepant Material Return) module, or you may transfer it back into Inventory using the Transfer tab .Once the DMR (discrepant material return) has been added and saved, a Debit Memo will be created in the Accounting System. Additionally, the corresponding entry will be created and the balance in the Accounts Payable Aging will adjust.

|