|

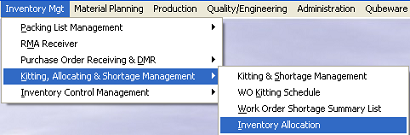

| Enter Inventory Mgmt/Kitting, Allocating & Shortage Management/Inventory Allocation Module |

|

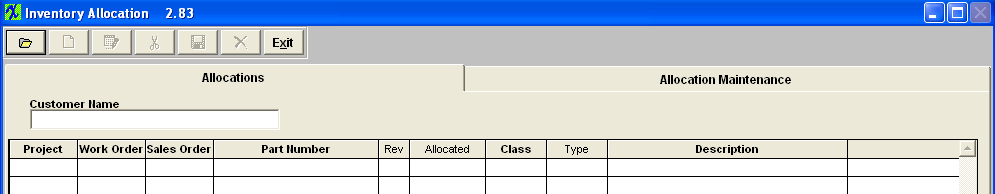

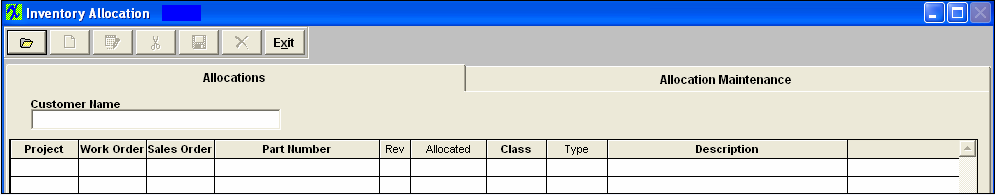

The following screen will appear:

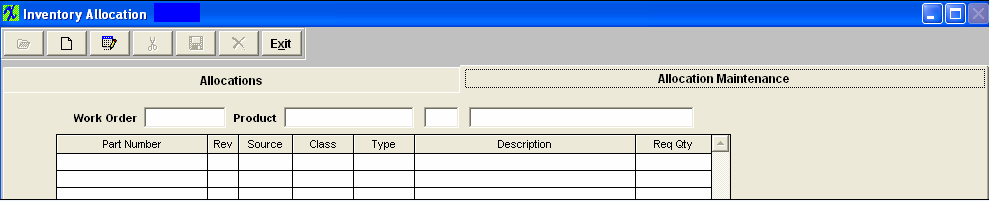

Depress the Allocation Maintenance tab

|

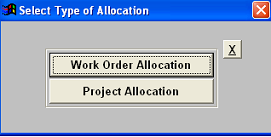

Depress the Add record action button and type in your password will bring up the following selection.

Depress the “Work Order Allocation” button.

|

|

|

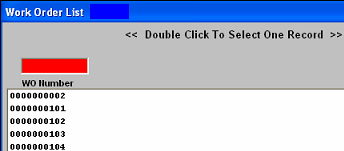

The following prompt will appear.

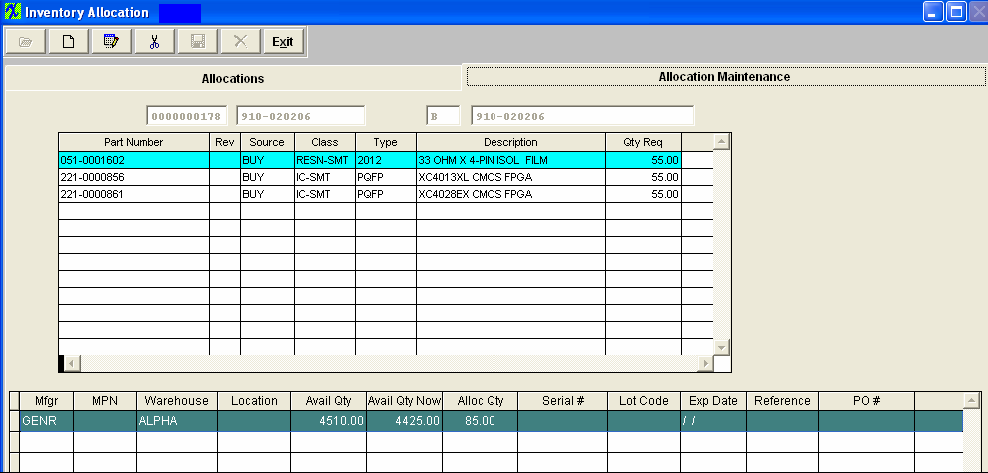

If you select “YES” then all available inventory will be allocated automatically to the selected work order. Edit any quantities allocated by selecting the Part Number (highlighted) in the upper screen table and changing the Alloc Qty for the desired manufacturer in the lower part of the screen. Save after all allocation editing has been completed.

If you select “NO” then the system will list out all part used within the Work order (per BOM) and require the users to go through and manually allocate inventory to each desired part.

|

|

|

The following Work Order selection screen will then become available. Select the desired work order by Typing in the Work Order Number or highlight the Work Order and double click.

|

|

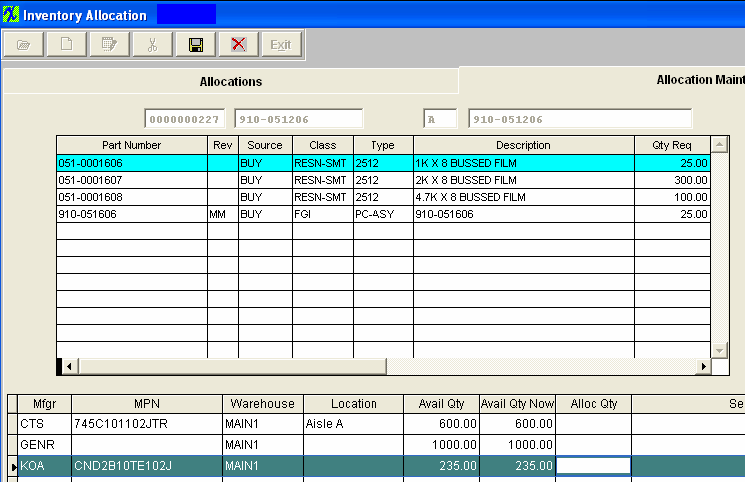

Particulars regarding that Work Order will populate the screen as displayed below:

- Highlight the desired part number you want to allocate. Inventory AVL information for that particular part will populate the lower portion of the screen.

- Type in the amount you want to allocate in the Alloc Qty column.

- Depress the Save record action button. The screen will update as follows:

Note that the Avail Qty column has updated to reflect the amount allocated. The Inventory Master has also automatically updated, and will now display the amount allocated (“reserved”).

|