Invoking Serialization after the Work Order is Started

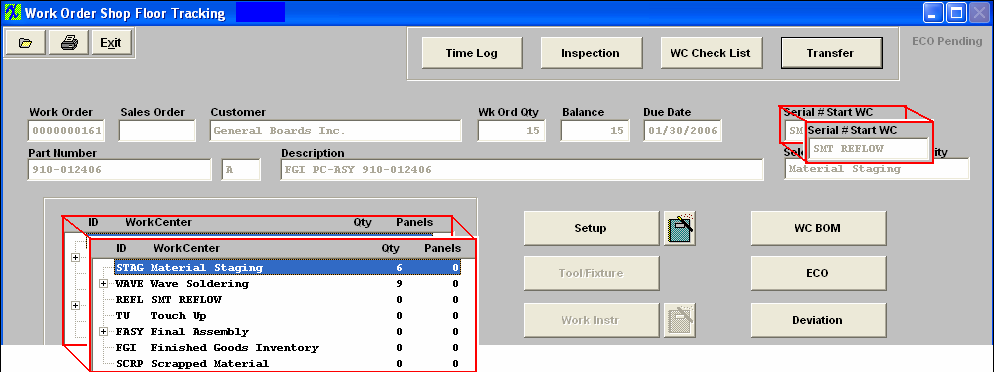

If you already have a Work Order started and then decide to invoke serialization, in order to assign serialization to a product with an open work order, in the Shop Floor Tracking Module, the parts must all be in a Work Center which is PRIOR to the Work Center in which serialization is to be applied.

Then the Work Center can be updated and the product moved BACK to the appropriate Work Centers after the product is serialized. If the Work Order has been completed and the product is in the Finished Goods Work Center, the user may move the product back to a “non-serial Work Center” and then serialize and update the Work Order. Then the user should move the parts back into the Finished Goods Work Center. If the parts in Finished Goods were already shipped, the user can use the Inventory Handling module to temporarily increase the finished goods to the needed quantity. Then they can be backed into the Work Order. After running these parts back down the chain, the user would use Inventory Handling to take the parts back out of inventory. |