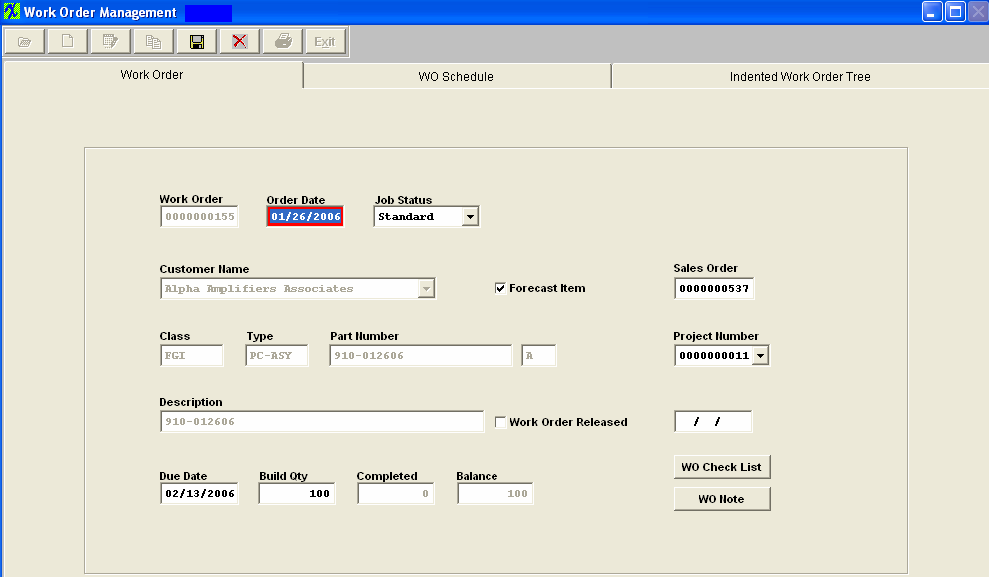

Find an existing Work Order

After a Work Order has been found, it may be edited by selecting the Edit Action button.

All fields available for editing will be enabled for modification. The fields which may be edited are:

Order Date, Job Status, Work Order Release, Due Date, Build Qty. The user may also add a note, or add or delete a parent work order. Note: Once a Kit has been flagged as "In Process" the Work Order Management module will NOT allow the users to change the Work Order status between Standard and Rework. For further detail see Article #2691 .

If the user wishes to change the Build Qty on a Work Order in process on the Floor the system will provide the users with what work center location they would like to reduce the qty from to match the new Work Order Qty. At this point the Kitting module will still show the original WO qty and what was picked. But if they depress the Update Kit button it will refresh the kit based off of the new WO Qty and now the qty that was adjusted will become WO-WIP. Which means it is available to fulfill any other demand that might be out there. Then upon Closing the kit the user has the option to cost that wo-wip to the kit or return it to stock. If they return it to stock it will have no affect on their Mfgr Variance for that work order.

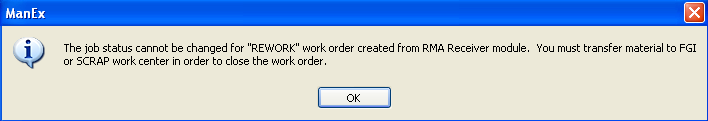

NOTE: Work Orders originated from an RMA Receiver will have "ReworkFirm" Job Status and users will NOT be allowed to change the Job Status, due to the fact that when the Work Order is created from RMA module all kitting, serial number, .... records are created and if user changes the WO status the system may loose track of these records. User will receive the following message if they try to change the job status on a Work Order that was originated from an RMA Receiver.

Since the material issued to the RMA is likely to be a defective assembly, or requires re-inspection, the work order must be completed by either transferring the material to FGI or to scrap to close the work order. Therefore, an RMA work order cannot be cancelled.

Also, users will NOT be allowed to edit or change the Bld qty because when product is brought into the system with an RMA Receiver it is then automatically issued as itself to the kit at that time.

At the conclusion of the modification process, the user may either Save the changes by depressing the Save changes action button or Abandon the changes by depressing the Abandon changes action buttons.

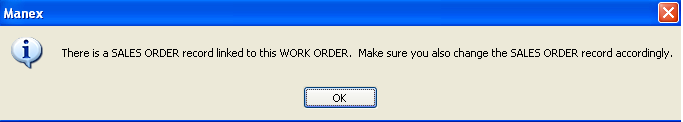

The following message will be displayed to the user if a SO is linked to a WO:

NOTE: The link is for reference only between the two modules and they are still individual records so when any changes are made to either the SO or the WO the change will not update or be carried forward to the other.

|