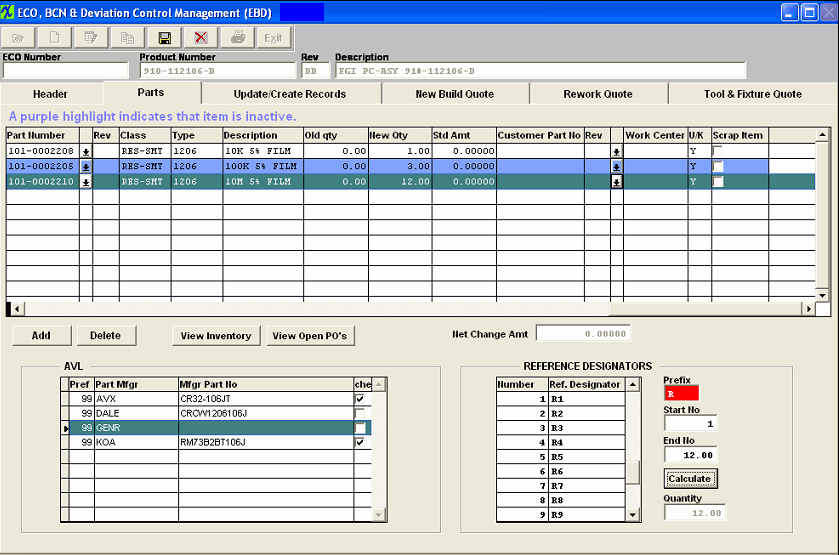

| Parts Tab |

|

Parts Tab Field Definitions - The Parts tab displays any additional changes or deletions of Bill of Material Components. If the part added has a status of "Inactive" within the Inventory Control Management, it will be highlighted in purple as an indicator to the user that this item is inactive at this time. If the user chooses to leave the inactive part on the ECO, that part number record status will automatically be changed to Active upon the "Update Records" button being depressed, so user will not have inactive parts listed on the BOM. The user will receive a warning that an XLS file has been created for reivew.

| Status |

The status of the component, either Add, Delete, Change. |

| Line No |

The Bill of Materials line number.

|

| Source |

The source of the component, either Buy, Make, Phantom or Consign.

|

| Part Number |

The internal number assigned to the component |

| Rev |

The revision character pertaining to the component part number |

| Class |

The classification of the component.

|

| Type |

The type within the classification of the component |

| Description |

The description of the component part number |

| Old Qty |

The quantityof thecomponent currently called for in the Bill of Materials.

|

| New Qty |

The new quantity ofthe component which will be called for. |

| Std Amt |

The standard cost per the Inventory Control Item Master multiplied by the net change in the number of components used.

|

| Customer Part No |

If there is a customer part number associated with the user’s part number, it will appear here.

|

| Rev |

The revision character associated with the Customer Part number.

|

| Work Center |

The work station where is component is 1st used in the assembly production process.

|

| U/K |

Valid entries for this field are “Y” – Yes used in Kit, “N” – Not used in Kit, “F” – Free Stock.The system will default the value to be “Y.”

|

| Scrap Item |

This field is for reference only, it will not affect any other modules. |

| Net Change Amount |

The sum of the Standard Amount column.

|

|

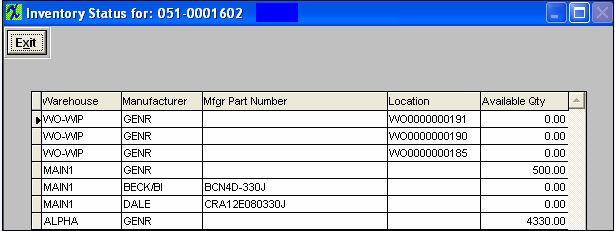

The following screen will be displayed, showing the currently available inventory information for the line item highlighted.

|

|

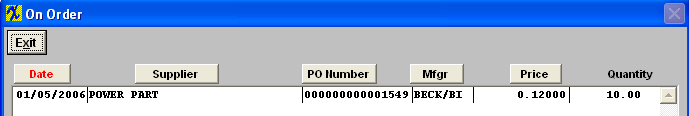

The following screen will be displayed, showing current Open PO for the line item highlighted: |

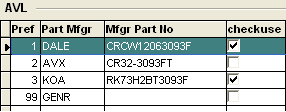

| AVL Information |

For the highlighted line item |

|

| Pref |

This is a number indicating the preference for use |

| Part Mfgr |

Displays the Part mfgr. name |

| Mfgr Part No |

Displays the Part mfgr. part number |

| Checkuse |

This box will be checked if this Mfg. and Mfg. Part number may be used |

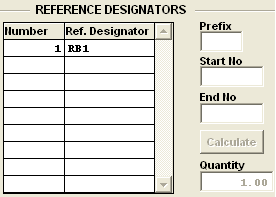

| Reference Designator |

For the highlighted line item |

|

| Number |

The number assigned to the reference designator.

|

| Ref. Designator |

The alpha numeric characters assigned to the Reference Designator number.

|

| Prefix |

The character assigned to all of the reference designator numbers.

|

| Start No |

The first Reference Designator number.

|

| End No |

The last Reference Designator number.

|

| Calculate (button) |

The button used to calculate the Reference Designator.

|

| Quantity |

The new quantity for which Reference Designators have been assigned.

|

|

|

|

|

|

|

|

|

|

| Article ID: 1741 |