To display or print a Report for a BOM, first find the BOM. (See Article #571).

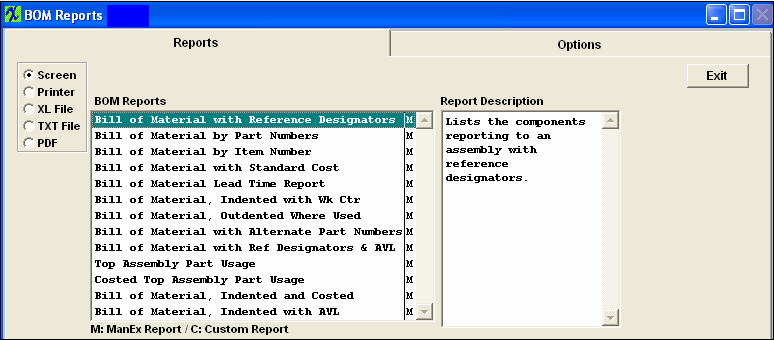

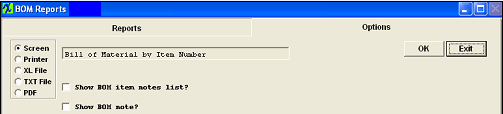

1. To access the reports, depress the Print action button at the top of the screen. The report screen will appear.

2. Select the output you desire by selecting one of the output radial selections at the top left of the screen, Screen, Printer, XL File, TXT File, or PDF.3. Highlight the report desired and click on the option tab. (The BOM reports will indicate in the Source column if the item is setup as Make/Buy or Make/Phantom, along with Consigned or Buy).

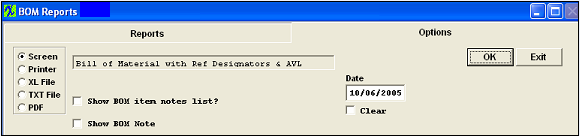

BILL OF MATERIAL WITH REFERENCE DESIGNATORS

|

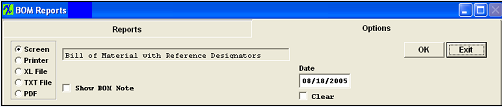

For the BOM with Reference Designators report check if you would like the BOM Notes to be displayed on the report.

Depress the OK button.

|

|

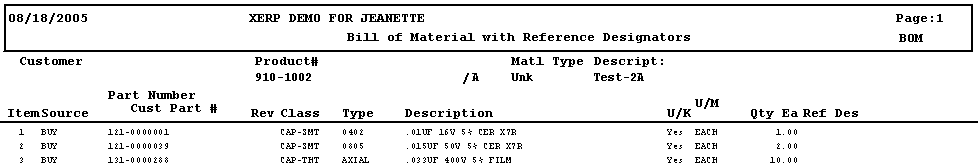

The following is printed

BILL OF MATERIAL BY PART NUMBERS

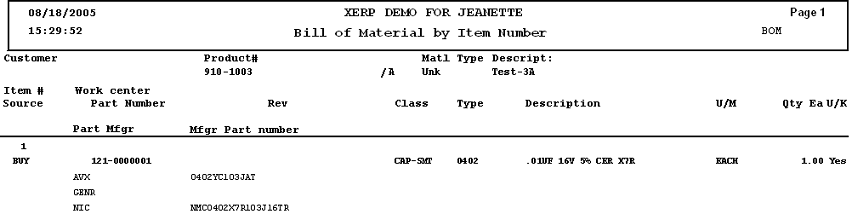

BILL OF MATERIAL BY ITEM NUMBERS

|

Check the boxes if you want the BOM item notes list and/or the BOM notes to be displayed on the report.

Depress Ok.

|

|

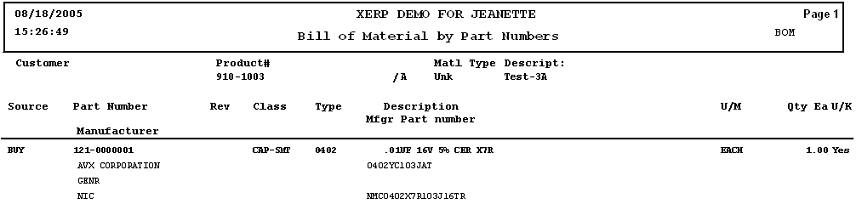

The following report will print:

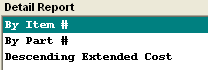

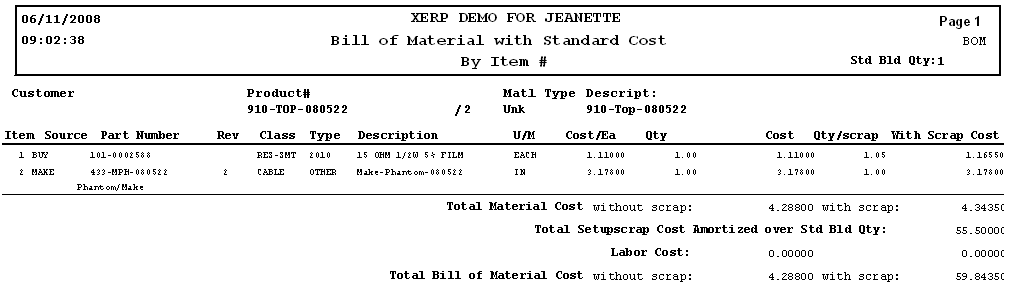

BILL OF MATERIAL WITH STANDARD COST

|

Choose By Item #, By Part #, or Descending Extended Cost from the Detail Report.

Depress Ok.

|

|

Note: This report takes into consideration the Std Bld Qty when calculating the setup scrap. You might find the cost calculated in SFT is different from the calculation shown on this report due to, that if the part UOM is "EACH" and the part has scrap % the code will round it up to next inter number.

a) For the PHANTOM parts in this report the standard cost calculated is based on their components (SUM of component's qty * component standard cost). Once the standard cost is calculated for the PHANTOM part, the report will treat the PHANTOM part as a single entity on the top assembly BOM and proceed as it was a BUY part with the std cost already entered.

b) If one of the component parts is a MAKE (not MAKE_BUY) and HAVE components assigned to it, the report will NOT show std cost of the parts itself, it will only show std cost of its subcomponents.

c) If one of the component parts is a MAKE (not MAKE_BUY) and does NOT HAVE parts assigned to it the report will show std cost of the part itself.

d) If one of the component part is a MAKE and MAKE_BUY the report will show price for the part itself and will show 0.00 costs for the subcomponents.

e) If one of the component part is a MAKE and a Phantom/Make the report will NOT display the std price for this part because the report will show the cost of this parts components.

Note: This report will only display the costs for ACTIVE parts and subassemblies as of the date of the report and will NOT include any parts that may have been identified as inactive either in the item master or in the obsolete date of the part on the BOM.

The values displayed should be in sync with the Cost Roll Up values. The following may be why the Standard Cost Roll is different from the Cost BOM Reports.a) On the costed BOM Report for a Make/Buy assembly we display the value of the BOM in the costed report, but that total is NOT used in subsequent rollups to higher levels only the standard cost is.

b) In Kit Default Setup , user can "Exclude Scrap and Setup Scrap" in Kitting, MRP, and Cost Rollup, and this will override the "Setup Stcrp" box in the BOM. Therefore, if user checks "Setup Stcrp" checkbox along with a Standard Bld qty in BOM header, but has the checkbox checked in Kit Default Setup to "Exclude Scrap and Setup Scrap" for Cost Roll, the Cost Roll will NOT calculate the Setup Scrap cost, but this report will always calculate the Setup Scrap cost and this will cause unfavorable Configuration Variances. For further detail on how Excluding Scrap and Setup Scrap values will affect the variances see Articles #3067, #3053, and #3320 .

The following report will print: This report ALWAYS includes ALL the parts (including the items flagged as "N" for Used in kit)

BILL OF MATERIAL LEAD TIME REPORT

|

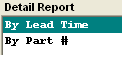

Choose By Lead Time, or By Part # from the Detail Report.

Check Ok.

The BOM with Lead Time report will add the lead time of the parent part into the lead time field. So if you have a child part with a Purchase lead time of 30 days, and a parent part with a lead time of 1 day for Kitting and 3 days for Production, the lead time of the child part will be 1+3+30 = 34.

|

|

The following report will print:

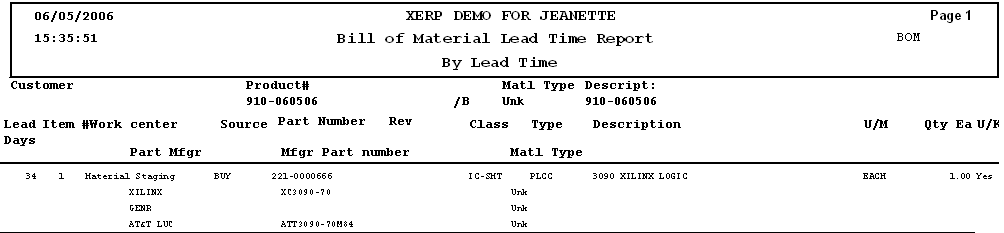

BILL OF MATERIAL, INDENTED WITH WORK CENTER

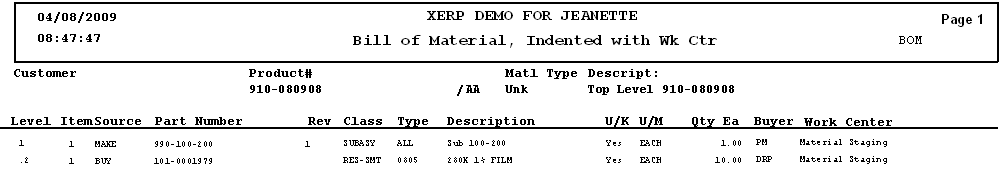

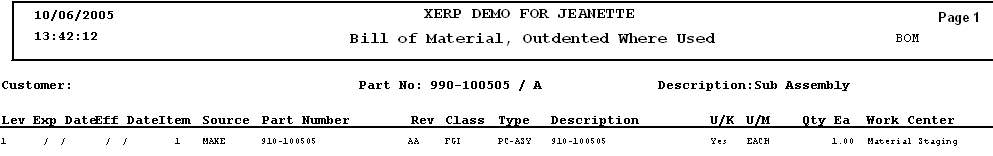

BILL OF MATERIAL, OUTDENTED WHERE USED

|

Select the Inventory Type by choosing the radial. Enter the Internal Part Number and Rev.

Check the box if you want the BOM items that are expired or not effective yet to be displayed on the report.

|

|

The following report will print:

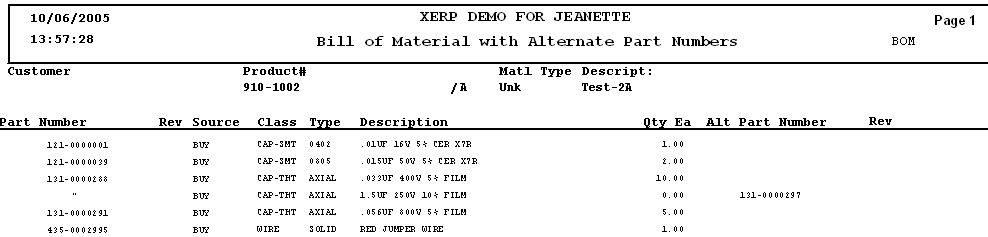

BILL OF MATERIAL WITH ALTERNATE PART NUMBERS

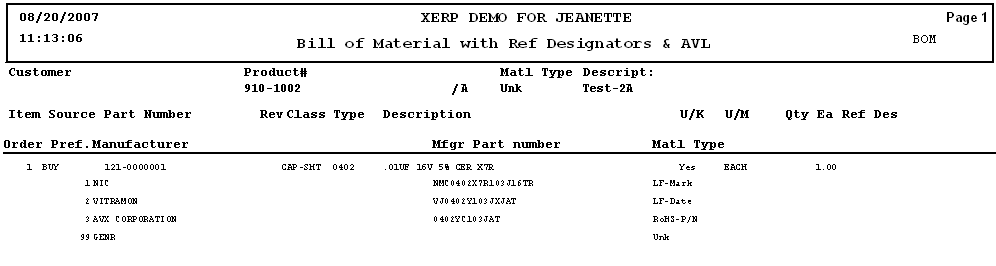

BILL OF MATERIALS WITH REFERENCE DESIGNATORS & AVL

|

Check the boxes if you want the BOM item notes list and/or BOM notes to be displayed on the report.

The AVL Order Pref Code will be displayed in front of the Mfgr and Mfgr PN information.

|

|

The following report will print:

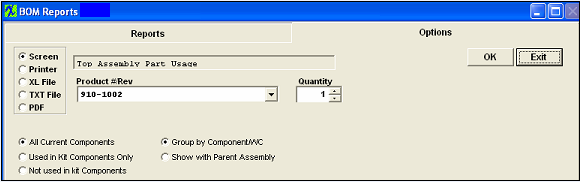

TOP ASSEMBLY PART USAGE

| Select the Product number and applicable revision.

Select the quantity by toggling on the up and down arrows.

Choose between All Current Components, Used in Kit Components Only and Not used in kit Components by clicking on the desired radial.

Choose between Group by Component/Work Center and Show with Parent Assembly by clicking on the desired radial.

Depress Ok.

|

|

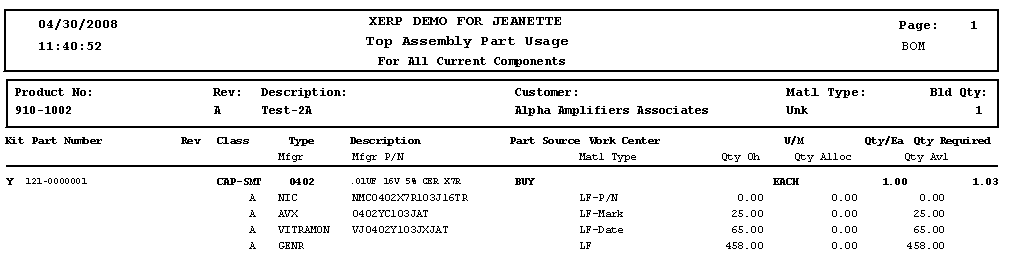

The following report is printed:

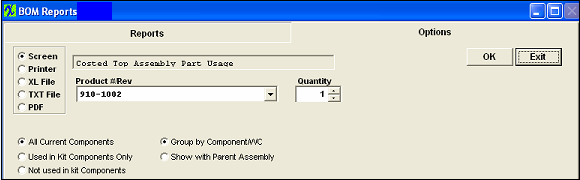

COSTED TOP ASSEMBLY PART USAGE

| Select the Product number and applicable revision.

Select the quantity by toggling on the up and down arrows.

Choose between All Current Components, Used in Kit Components Only and Not used in kit Components by clicking on the desired radial.

Choose between Group by Component/Work Center and Show with Parent Assembly by clicking on the desired radial.

Depress Ok.

|

|

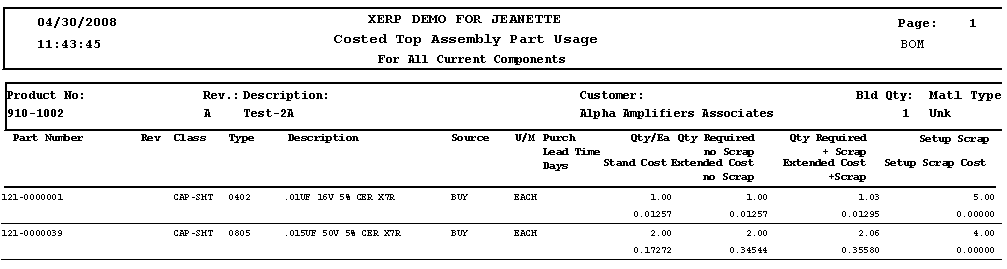

The following report will print:

BILL OF MATERIAL, INDENTED AND COSTED - the following rules are applied to make sure that the Cost is properly calculated:

a) If one of the component parts are MAKE (not MAKE_BUY) and have components assigned to it, the report will NOT show cost of the parts itself, it will only show cost of its subcomponents.

b) If the component part is MAKE (not MAKE_BUY) and has no parts assigned to it the report will show cost of the part itself.

c) If the component part is MAKE and MAKE_BUY the report will show price for the part itself and will show 0.00 costs for the subcomponents and display the following message "Standard price of the subcomponents of this part is omitted, because the part is marked as a MAKE/BUY and report will consider this part's own cost.".

d) If the component part is a MAKE and a Phantom/Make the report will not display the std price for this part because the report will show the cost of this parts components.

Note: Only Approved AVL's will be displayed on report. Note: This report will only display the costs for ACTIVE parts and subassemblies as of the date of the report and will NOT include any parts that may have been identified as inactive either in the item master or in the obsolete date of the part on the BOM.

BILL OF MATERIAL, INDENTED WITH AVL - This report will list out the Indented BOM information, and the Approved AVL information.

The BOM reports will indicate in the Source column if the item is setup as Make/Buy or Make/Phantom, along with Consigned or Buy.

|